JISHAN REPAIR MOISTURE-PROOF ALKALI REMOVAL NO. 1

A & B mix

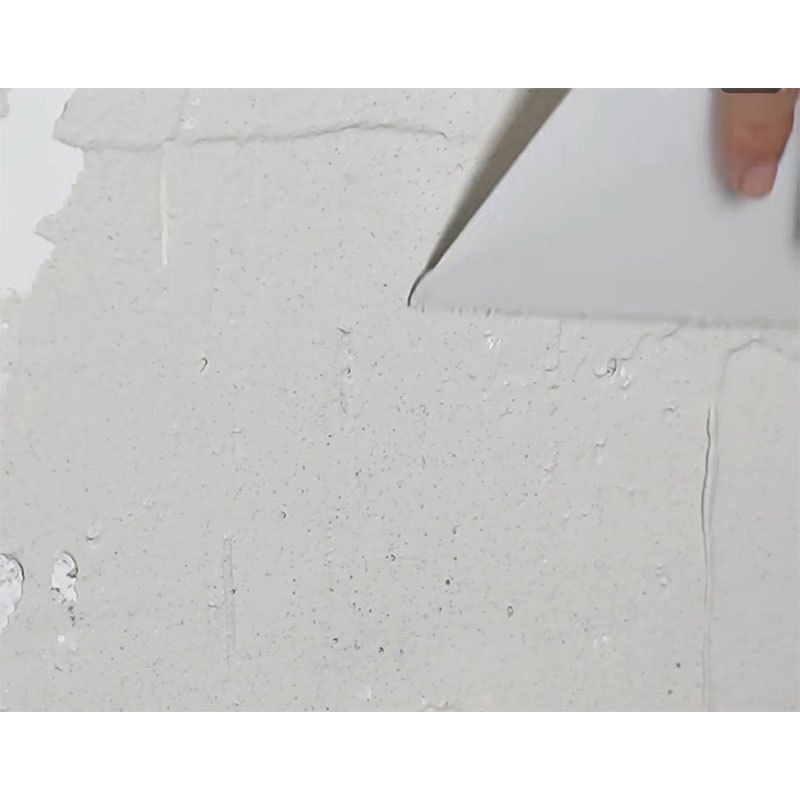

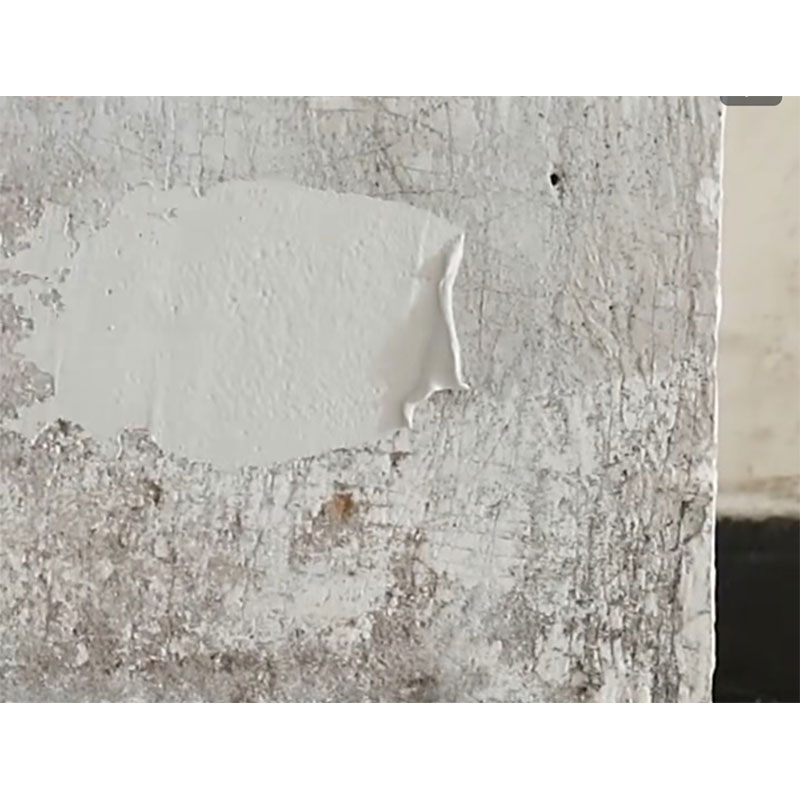

Using Scrape skim coated

*Moisture-proof and alkali-removal: widely used in the treatment of alkali-resistant, damp, mildewed and peeling of indoor and outdoor walls.

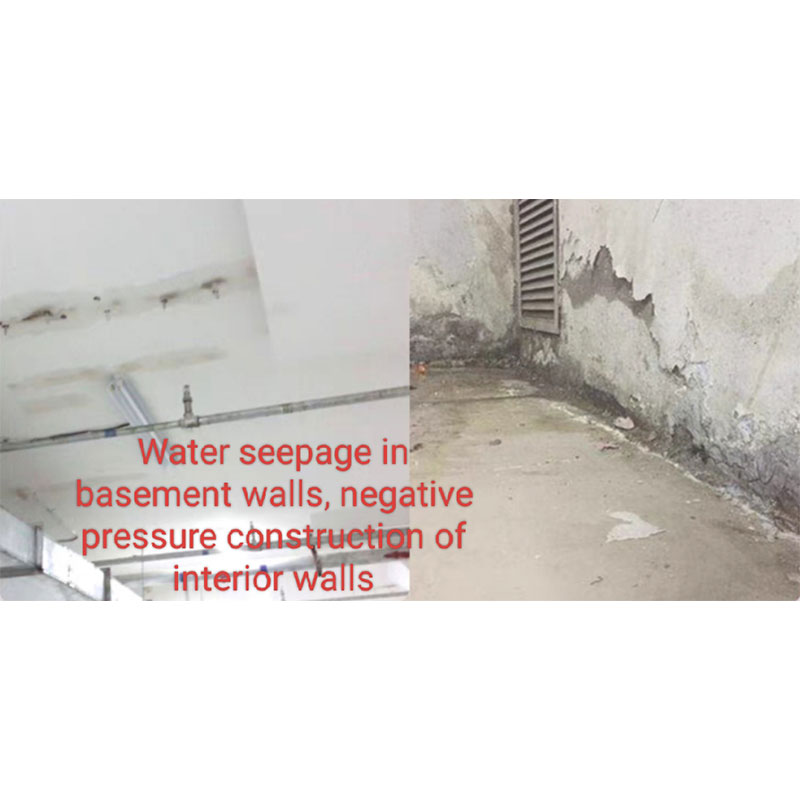

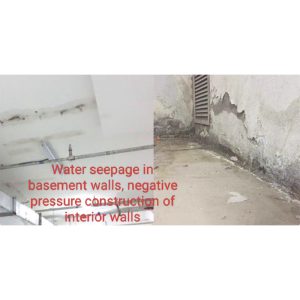

*Negative pressure anti-seepage: widely used in the treatment of micro-seepage on the back surface of retaining wall basements side wall, toilet wall,elevator shafts, pools outder wall, tunnels, garages, etc.

- Negative Pressure Anti-Seepage

- High-Pressure Waterproofing

- Porcelainization Technology

- Description

Description

Product Ingredient

Main ingredients of Moisture-Proof Alkali Removal No. 1: Refined natural inorganic mineral powder, sand, water, inorganic additives, etc.

Features

- Uses a pure water-based, fully inorganic formula, containing no organic glues or materials, offering excellent natural antibacterial and antifungal effects, odorless, non-toxic, zero formaldehyde, zero VOCs, zero benzene.

- Employs a unique high-penetration porcelainizing coating technology that deeply penetrates the concrete layer and reacts to cross-link, tightly bonding to the wall without forming hollow spaces; the active minerals in the product react with silicates to form a dense porcelain layer, effectively resisting moisture penetration while also exhibiting excellent resistance to acids, alkalis, and permeability, effectively countering the corrosion from alkalis, nitrates, and sea sand.

Construction Technology

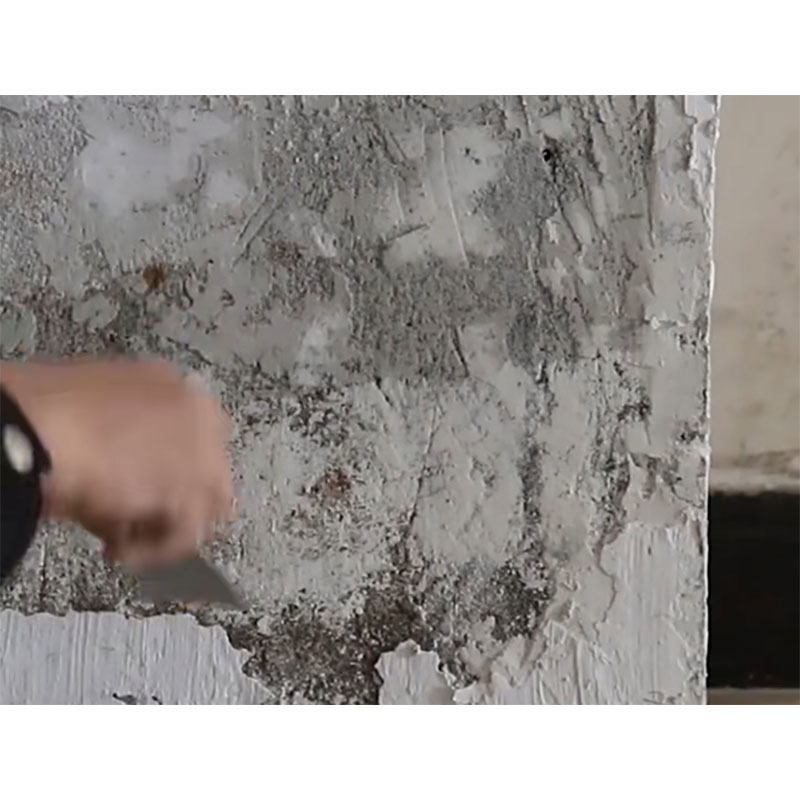

- Clean the concrete surface thoroughly, removing any areas that are completely powdered or hollow, and expand by 20~30cm. Clean with a steel brush to ensure the base layer is solid and clean;

- In cases of severe alkali efflorescence on walls, use an inorganic alkali-removing agent sprayed to clean until no obvious alkali crystals form;

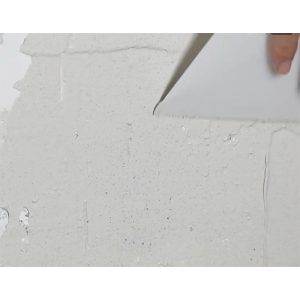

- Thoroughly moisten the base layer with clean water, and once the base is wet without standing water, proceed with the putty application.

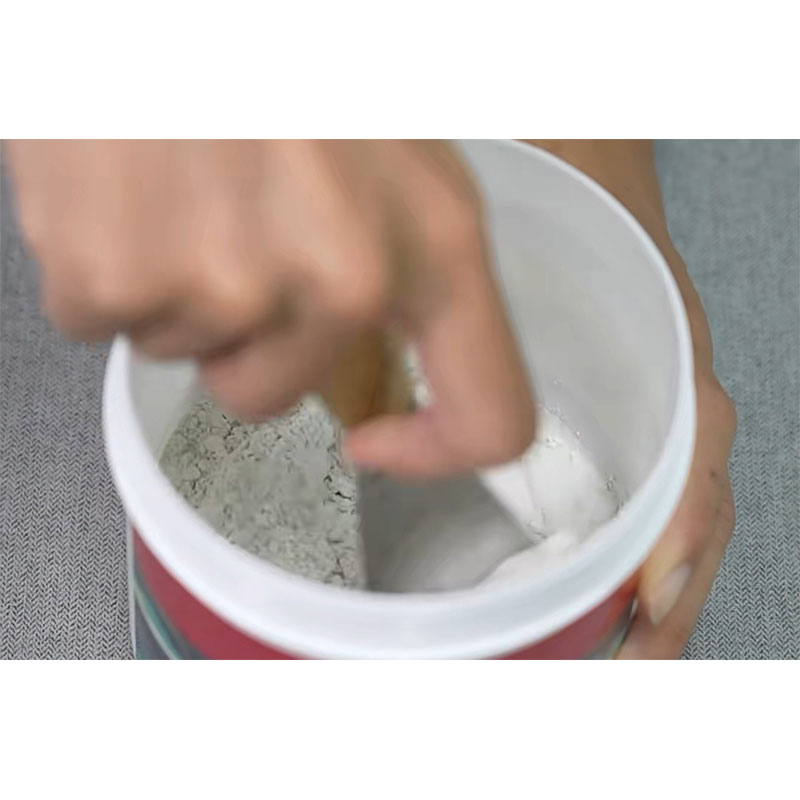

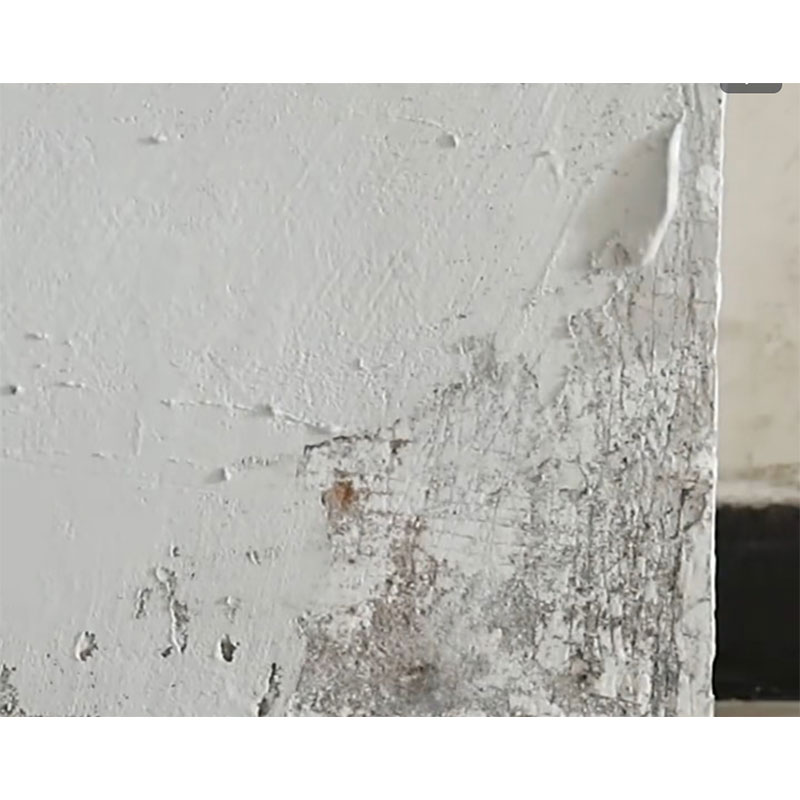

- Mix components A and B according to the specified ratio, stirring until the mixture is uniform and free of clumps; apply the mixed mortar evenly over the treated concrete base layer, allow to dry for 24 hours without any visible water marks, then apply a second coat;

- After two coats, if no further water marks appear, proceed directly with applying putty and painting the walls; if persistent water marks continue, reapply the coating until no visible water marks remain before proceeding with subsequent construction (applying putty, undercoat, and topcoat).

Scope of Application

- Moisture-Proof Alkali Removal: Widely used for treating alkali efflorescence, moisture return, mold, and peeling due to dampness on both interior and exterior walls;

- Negative Pressure Anti-Seepage: Commonly used for minor seepage treatment in bathrooms, basements, elevator shafts, pools, tunnels, garages, and other backwater surfaces;

- High-Pressure Waterproofing: Extensively used in high water pressure, long-term submerged environments such as landscape pools, swimming pools, and fire water tanks for waterproofing.

Precautions

- When working, wear protective gear, and if contact with the eyes occurs, rinse immediately with plenty of water;

- Prepared mortar must be used within 60 minutes; materials not mixed should be sealed immediately after opening the can to prevent spoilage;

- The suitable working temperature for construction is between 5°C and 35°C. Do not work during rain, snow, or in wind conditions exceeding Beaufort scale 5;

- Before the mortar is fully dried and hardened, protect it from rain washout and avoid application on icy or frosty bases. Do not add other materials to this product to avoid adverse reactions.

- When there is visible water under negative hydrostatic pressure, it is recommended to first plug the leak points; otherwise, the water will overflow to other areas.

- This product features an inorganic mineral formula. The strength of the product and the bond of the mortar will improve over time, with the physical properties strengthening progressively, reaching optimal performance theoretically after three months.

Packaging and Storage

- The product is an inorganic mineral formula. During storage, mineral powder may settle, but shaking the container before use will redistribute the contents evenly without affecting product performance.

- Packaged in sealed barrels and transported as general building materials, precautions should be taken during transport to avoid exposure to sunlight and rain, and to prevent squeezing and collisions to keep the packaging intact.

- Packaging must be stored and transported upright and kept in a cool, dry place between 5°C and 35°C.

- Shelf life: 18 months.

Standards

GB18582-2020

Statement

Please follow the instructions in the user manual for proper construction. We will not be held responsible for any losses resulting from your improper use. For any inquiries, please consult your local dealer or our technical service department.