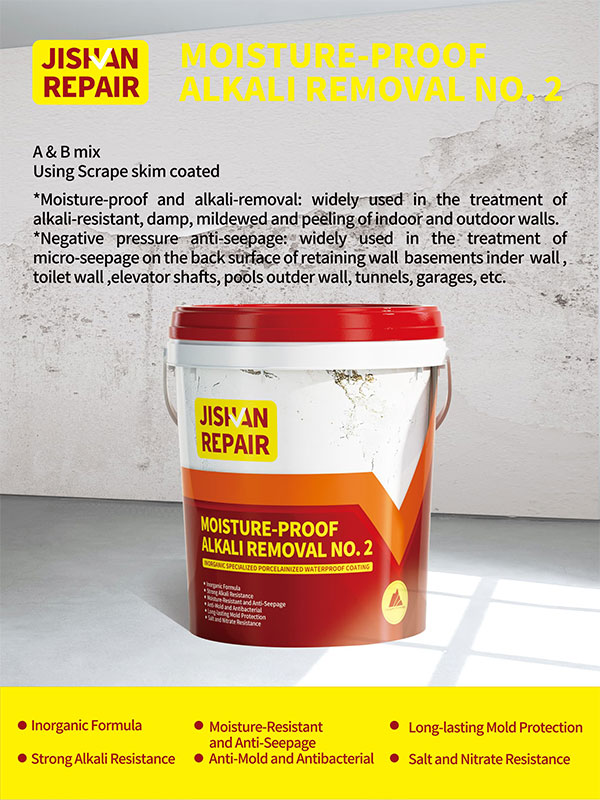

JISHAN REPAIR MOISTURE-PROOF ALKALI REMOVAL NO.2

A & B mix

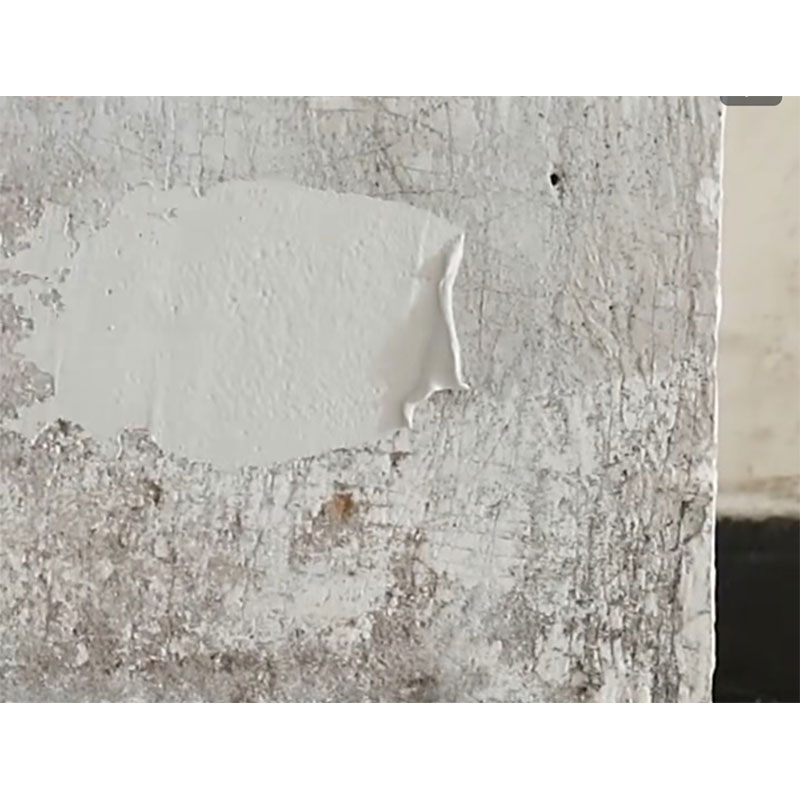

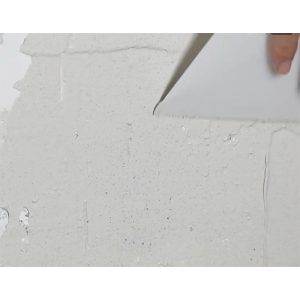

Using Scrape skim coated

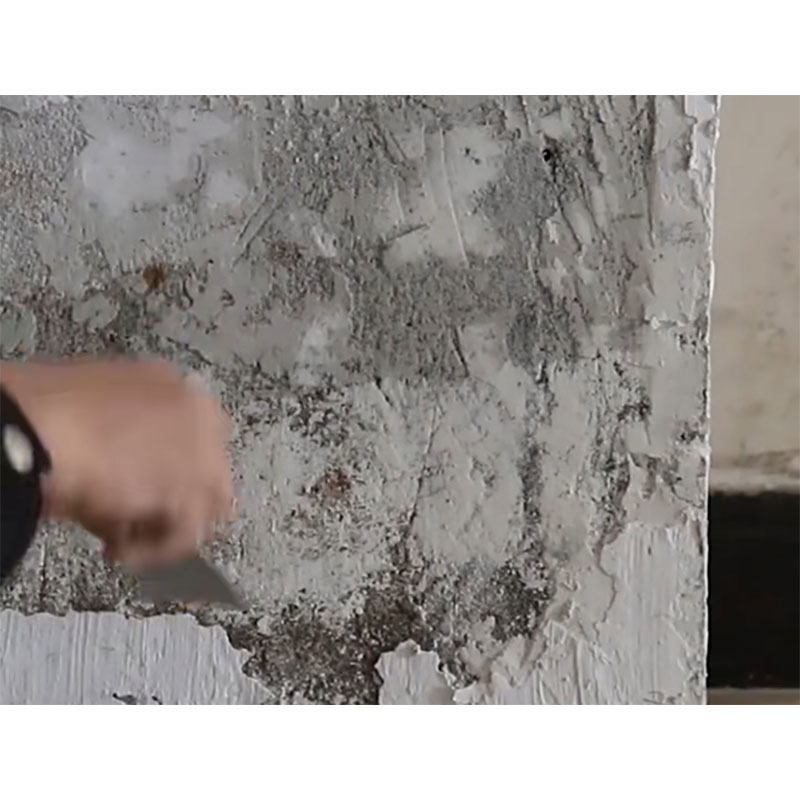

*Moisture-proof and alkali-removal: widely used in the treatment of alkali-resistant, damp, mildewed and peeling of indoor and outdoor walls.

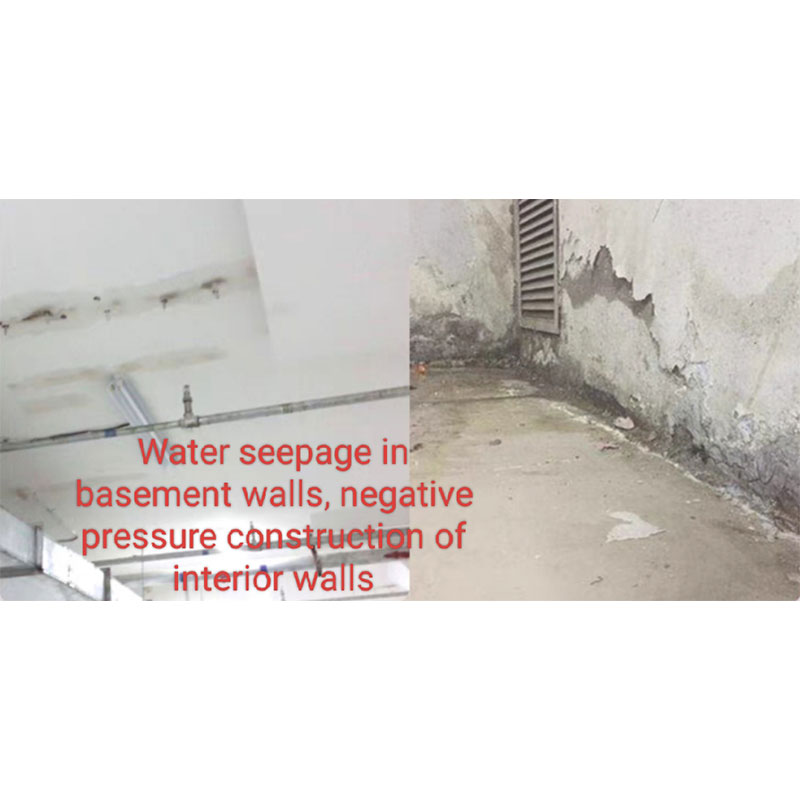

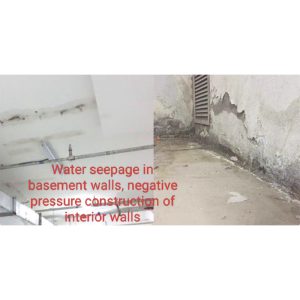

*Negative pressure anti-seepage: widely used in the treatment of micro-seepage on the back surface of retaining wall basements inder wall, toilet wall,elevator shafts, pools outder wall, tunnels, garages, etc.

- Strong Alkali Resistance

- Salt and Nitrate Resistance

- Moisture-Resistant and Anti-Seepage

- Anti-Mold and Antibacterial

- Inorganic Formula

- Long-lasting Mold Protection

Mold Hazard: In continuously damp environments, walls, panels, and clothing are prone to mold growth, fostering various molds and insects that release volatile organic compounds (mVOCs), resulting in a pungent mold odor.

Mold odors and toxins not only cause severe irritation to the cornea but also pose serious risks to human health through inhalation, skin contact, affecting the liver, kidneys, respiratory system, and immune functions, potentially leading to rhinitis, and may cause neurological and endocrine disorders, immune suppression, carcinogenic and teratogenic effects, liver damage, and acute or chronic health impacts.

- Description

Description

Product Ingredient

Refined natural inorganic mineral powder, sand, water, inorganic additives.

Scope of Application

- This product is extensively used in the prevention of alkali efflorescence, damp reversion, mold, and peeling due to moisture on both interior and exterior walls.

- This product has excellent porcelain sealing properties and is suitable for use in moist environments such as bathrooms, basements, and elevator shafts.

Features

- This product is a pure water-based, fully inorganic formula, containing no organic emulsions or adhesive materials, offering excellent natural antibacterial and antifungal effects, odorless, non-toxic, and contains zero formaldehyde and VOCs.

- This product features a unique high-penetration porcelainizing coating technology that deeply penetrates into the concrete layer and tightly bonds with the wall; it reacts with silicates to form a dense porcelain layer, effectively resisting moisture penetration while also providing excellent resistance to acids, alkalis, and corrosion from alkali, nitrate, and sea sand.

- This product uses highly reactive inorganic materials that tightly bond with concrete and putty layers, minimizing the risk of hollow spaces.

Application Process

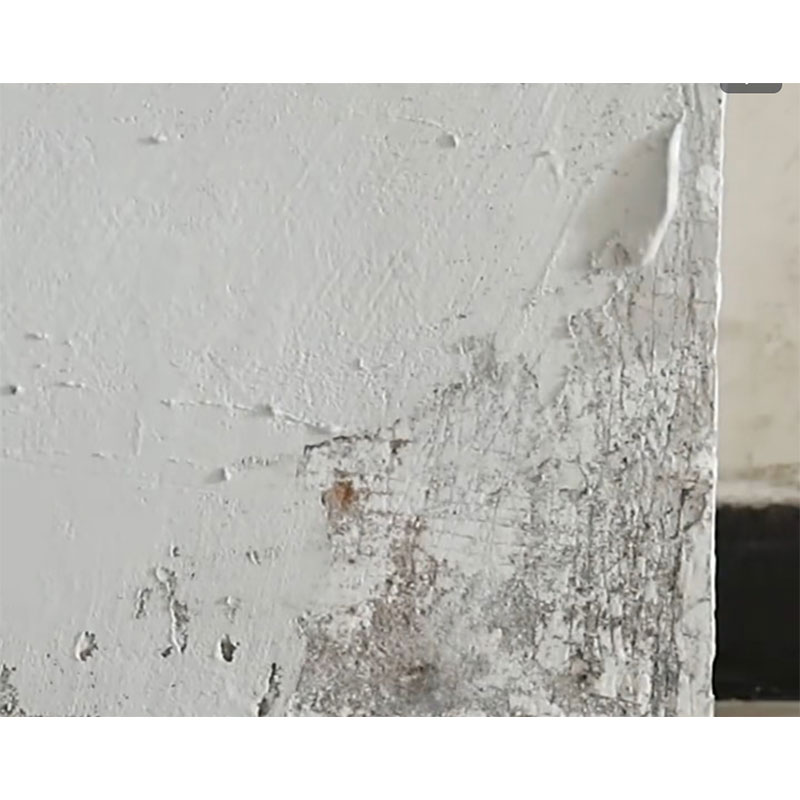

- Clean the construction base surface to ensure it is solid with no dust, and moisten with clean water to a damp state, but without standing water.

- Mix components A and B thoroughly according to the specified ratio, adjusting with water as needed based on actual construction conditions.

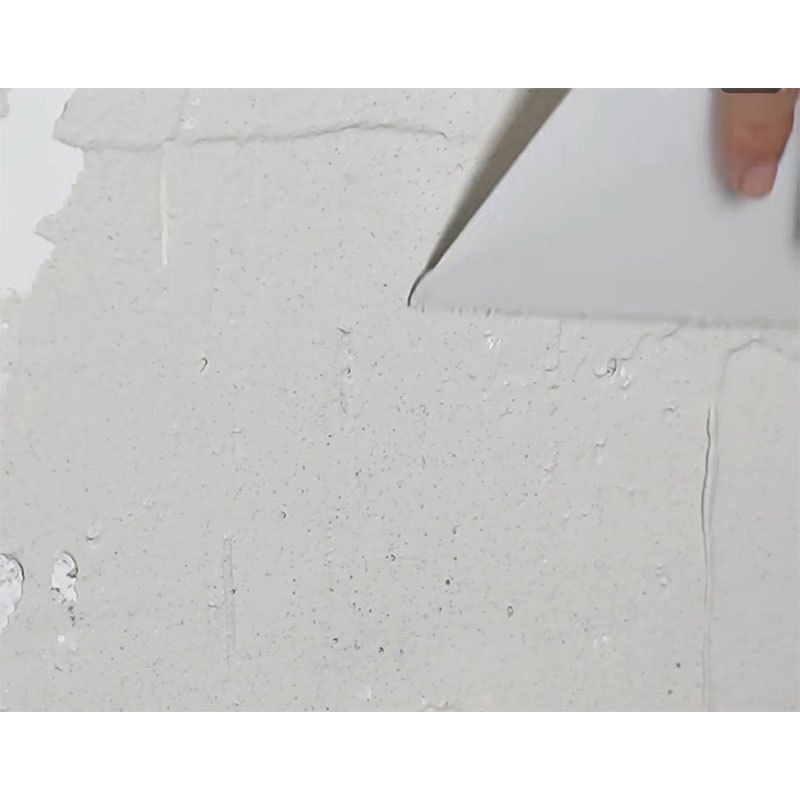

- Apply using a roller, brush, or spraying machine; adhere strictly to the crisscross method during application to prevent missed areas.

- The waterproof coating should be applied in at least two layers, with each layer allowed to air dry for 24 hours. The coating should dry to a whitish appearance.

- When applying to a wet surface, continue to brush until no obvious water marks are visible before proceeding with the application of putty and wall paint; if stubborn water marks persist, apply the same mixture by rolling until no water marks remain, then continue with subsequent processes (applying putty, undercoat, and topcoat).

Precautions

- Store in a cool, dry, safe location to prevent accidental ingestion by children.

- This product is resistant to alkali and moisture but does not provide protection against positive hydrostatic pressure. If there is visible water under pressure, it is recommended to first plug the leak; otherwise, the water may continue to flow to other areas, causing prolonged moisture that can corrode structural elements.

- This product should be applied to concrete surfaces and not directly on putty layers, as the moisture and humidity drawn through the putty can cause blistering and compromise the overall moisture barrier.

- Mixed materials must be used within 90 minutes, and materials that have not been mixed should be immediately sealed after opening to prevent spoilage.

- When using this product in special environments, test it first. Do not mix this product with products from other manufacturers or add any other materials to it, as this may cause adverse reactions.

- The suitable ambient temperature for application is between 5°C and 35°C (the higher the ambient temperature, the faster the curing).

Packaging and Storage

- Packaged in sealed containers and transported as general chemical building materials. Protect from sunlight and rain during transport and avoid squeezing and collisions to keep the packaging intact;

- Packaging must be stored and transported upright, and kept in a cool, dry place between 5°C and 35°C;

- Shelf life: 18 months.

Standards

GB18582-2020

Statement

Please follow the instructions in the user manual for proper construction. We will not be held responsible for any losses resulting from your improper use. For any inquiries, please consult your local dealer or our technical service department.